What Is a Shot Blasting Chamber?

Shot blasting chamber is a key element in the surface preparation process in the metal industry. Its design and operation directly impact the cleaning efficiency, the quality of the final paint coating, and the overall operating costs of the equipment. Therefore, understanding its structure and operating principles is crucial both during the design phase of the production line and when upgrading existing systems.

In this article – prepared by a team of experienced engineers and specialists from INGRITECH – we explain how a shot blasting chamber is constructed, what components it consists of, and how it operates in practice.

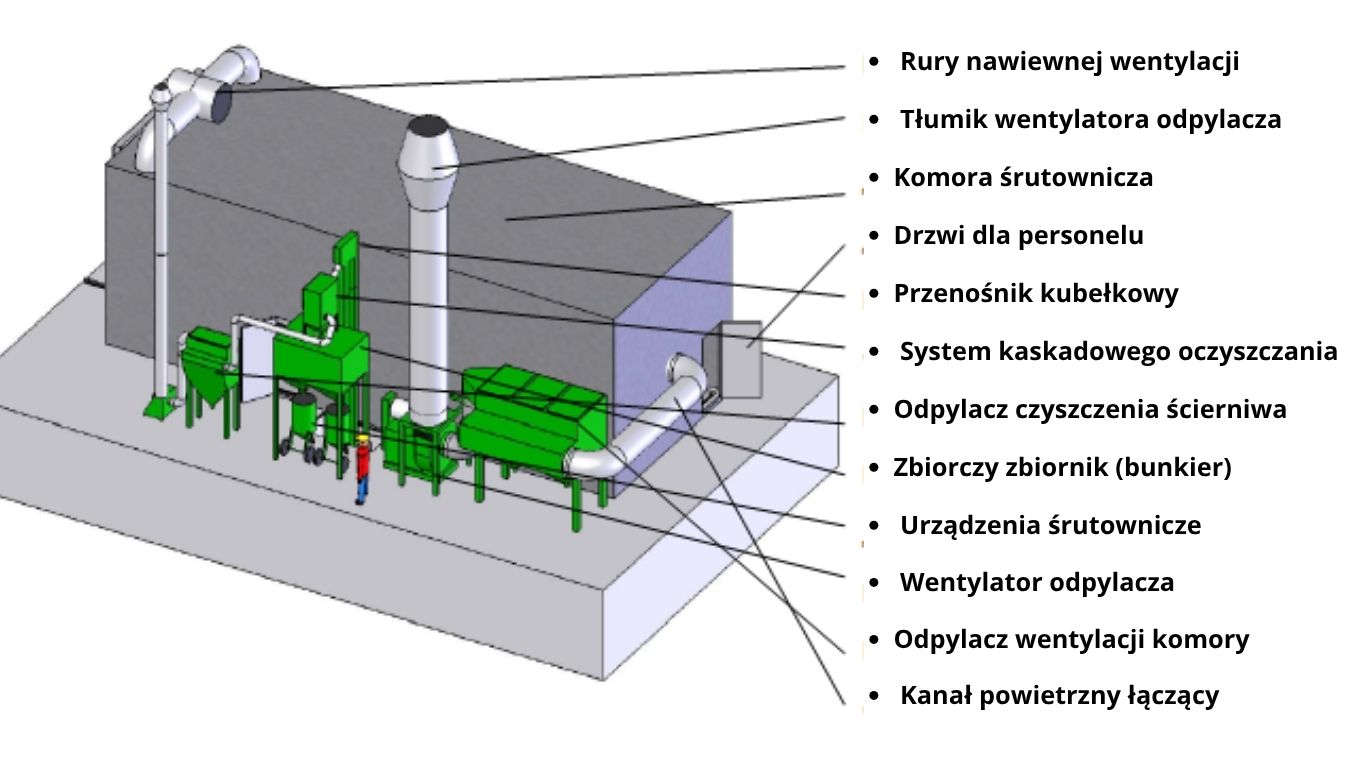

Shot Blasting Chamber – Key Components

The shot blasting chamber is an advanced industrial device whose effectiveness comes from precisely designed and integrated components. Each part directly impacts surface cleaning quality, work safety, and operating costs. Below are the main components of a modern shot blasting chamber:

1. Chamber Housing – Wear-Resistant Structure

The chamber is built with a solid steel structure, with interior walls protected by wear-resistant linings – typically made of rubber, manganese, or steel. This prevents damage from rebounding shot and extends the chamber’s lifespan. Acoustic insulation also reduces noise for improved operator comfort.

2. Blasting System – Turbines or Nozzles

Rotor turbines or pneumatic nozzles propel the abrasive media, such as low-carbon steel shot. These components determine the process efficiency. The higher the power and precision, the better the surface cleaning. The system is selected based on the application type and client requirements.

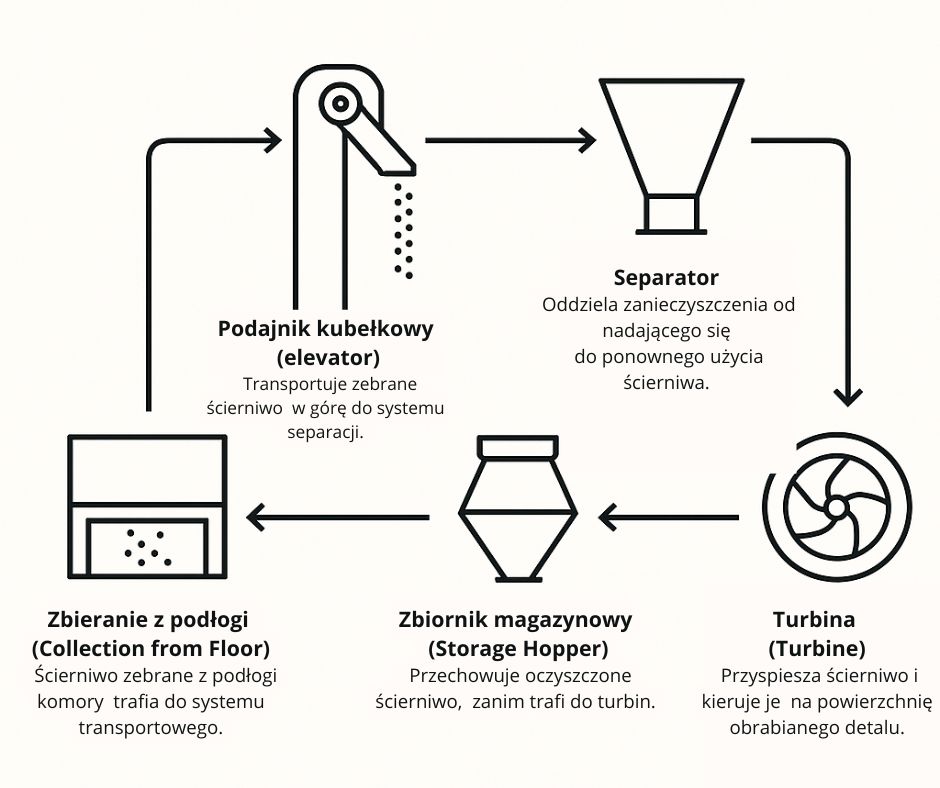

3. Abrasive Transport and Recycling System

The used abrasive is automatically collected and transported to a separator. There, contaminants are removed, and clean shot is reused in a closed-loop system – lowering costs, reducing material consumption, and improving production efficiency.

4. Air Filtration System – Cleanliness and Safety

Modern blasting chambers are equipped with cartridge or bag dust collectors. Effective filtration removes airborne particles, ensuring compliance with environmental standards (e.g., GIOŚ) and workplace comfort. A well-designed filtration system protects worker health and system components.

5. Control Panel – Full Process Management

A control panel integrated with an automation system manages the chamber. Operators use PLC controllers and intuitive HMI interfaces to monitor turbine speed, abrasive flow, filter condition, and work cycle in real time. This ensures quick response and optimal process control.

How a Shot Blasting Chamber Works – Step by Step

- The operator loads the workpiece into the chamber (manually or automatically).

- The system activates turbines or nozzles that blast abrasive onto the surface.

- The abrasive mechanically removes rust, scale, paint, or other contaminants.

- Used shot is collected and filtered through the recycling system for reuse.

- Dust is extracted by the filtration system, and clean air is returned to the workspace.

Types of Shot Blasting Chambers and Their Applications

The appropriate type of chamber depends on production scale, part size, and required throughput. See the comparison of common solutions below:

| Chamber Type | Application | Characteristics |

|---|---|---|

| Cabin Chamber | Medium and large parts | Manual operation, flexible workflow |

| Pass-Through (Tunnel) Chamber | Mass production | Automated part feeding, high efficiency |

| Drum Chamber | Small loose parts | Batch processing, compact design |

- Working area – tailored to part size and geometry

- Turbine type and efficiency – impacts cleaning quality

- Abrasive media – steel, stainless, or non-metallic options

- Dust collection – must meet health and safety standards

- Automation – integration with production lines

Discover why steel shot is the safest and most effective medium for metal surface treatment.

Why Invest in Modern Shot Blasting Systems?

A modern shot blasting chamber offers time and material savings, process consistency, and workplace safety. Properly designed filtration reduces dust emissions and meets environmental regulations (GIOŚ). Meanwhile, abrasive recycling greatly lowers operating costs.

Conclusion

The shot blasting chamber is a complex yet highly effective and efficient solution for modern metal surface preparation. Its precise design and thoughtful operation greatly influence the quality of the final product and the overall production efficiency. By choosing innovative solutions from INGRITECH, you’re investing not only in proven, modern technology but also in comprehensive technical support that translates into optimized processes and long-term business benefits.

Need Technical Advice or a Quote?

Check out our steel shot product range, which meets current safety standards and effectively replaces quartz sand in abrasive blasting. Contact our technical advisor – we’ll help you choose the right abrasive.