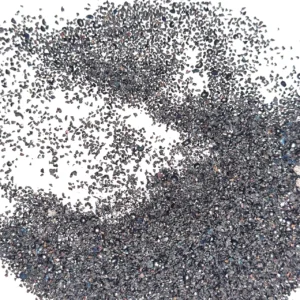

Description

During the manufacturing process, thermal drying is applied, further enhancing its mechanical properties. Each batch undergoes rigorous quality control, with samples stored for laboratory testing. The desired working mix can be achieved by combining different grain size fractions.

Chemical Composition (% by weight)

| Component | Content (%) |

|---|---|

| C (Carbon) | 0.10–0.17 |

| Si (Silicon) | 0.10–0.25 |

| Mn (Manganese) | approx. 1.00 |

| P (Phosphorus) | ≤0.035 |

| S (Sulfur) | ≤0.035 |

Physical Properties

| Property | Value |

| Durability (tests) | 3000–3500 cycles |

| Hardness | HRc 40–45 / HV 400–480 |

| Specific Density | approx. 7.5 kg/dm³ |

| Bulk Density | approx. 4.4 kg/dm³ |

| Microstructure | Bainitic |

Applications

1. Foundries – Steel shot used for removing oxide layers and sand from steel, cast iron, and non-ferrous metal castings.

Recommended fractions:

- Granular iron: S230, S280, S330, S390, S460, S550, S660, S780

- Steel casting: S280, S330, S390, S460, S550, S660, S780, S930

- Ductile iron: S170, S230, S280, S330, S390, S460, S550, S660

- Non-ferrous metals (Al, Cu): S170, S230

2. Steel mills, forges, rolling mills – Rust removal, surface roughening, preparation for coatings.

Recommended fractions:

- Semi-finished products: S230, S280, S330, S390, S460, S550, S660

- Steel structures: S170, S230, S280, S330

- Sheet metal: S110

- Steel profiles: S170, S230, S280, S330

- Pipes: S170, S230

- Rail tracks: S170, S230

3. Polishing – Surface finishing of tools and large steel components.

Recommended fractions: S110, S170

4. Shot Peening – Enhancing mechanical strength and fatigue resistance.

Recommended fractions: S170, S230, S280, S330

- Size Characteristics:

| Standard Sieve Opening Size, mm | S1110 | S930 | S780 | S660 | S550 | S460 | S390 | S330 | S280 | S230 | S170 | S110 | ||

| 4.75 | ||||||||||||||

| 4.00 | 0 | |||||||||||||

| 3.35 | 0 | |||||||||||||

| 2.80 | >90 | 0 | ||||||||||||

| 2.36 | >97 | >90 | 0 | |||||||||||

| 2.00 | >97 | >85 | 0 | 0 | ||||||||||

| 1.70 | >97 | >85 | <5 | 0 | ||||||||||

| 1.40 | >97 | >85 | <5 | 0 | ||||||||||

| 1.18 | >97 | >85 | <5 | 0 | ||||||||||

| 1.00 | >96 | >85 | <5 | 0 | ||||||||||

| 0.85 | >96 | >85 | <10 | 0 | ||||||||||

| 0.71 | >96 | >85 | <10 | |||||||||||

| 0.60 | >96 | >85 | 0 | |||||||||||

| 0.50 | >97 | <10 | ||||||||||||

| 0.43 | >85 | |||||||||||||

| 0.36 | >97 | |||||||||||||

| 0.30 | >80 | |||||||||||||

| 0.18 | >90 | |||||||||||||

| 0.13 | ||||||||||||||

Explanation:

The number in the table indicates the maximum or minimum allowable percentage for a given abrasive size passing through the specified sieve opening.

Symbols such as “>90” or “>85” indicate that more than 90% or 85% of the abrasive should be smaller than the sieve opening.

Packaging and Delivery

✔ Standard bags 25 kg (1000 kg pallet)

✔ Custom packaging available upon request

✔ Quality certifications: ISO 9001, MSDS, REACH

✔ Timely deliveries and flexible logistics

📞 Contact us for more details!