Dear Sir or Madam,

We are pleased to introduce INGRITECH — your trusted partner for high-quality steel shot supplies from renowned Ukrainian manufacturers.

We deliver reliable abrasive materials tailored to the most demanding processes such as cleaning, roughening, and surface preparation.

Why choose INGRITECH?

✅ Fast order processing – most deliveries completed within 2–3 business days

✅ Flexible cooperation terms – individual approach to every client

✅ Deliveries throughout Poland and the European Union

✅ Professional technical advice and support at every stage

✅ Convenient and secure payment options

On request, we also provide material samples and assistance in selecting the right abrasive for your specific application.

Applications of our abrasives

INGRITECH abrasives are widely used across many industries, including:

- Blasting of steel structures

- Surface cleaning before painting, galvanizing, and metallizing

- Reconditioning of foundry molds and industrial parts

- Processing concrete, stone, and metal surfaces

- Anti-corrosion and renovation works in heavy industry and shipyards

- Surface preparation for paint systems and protective coatings

- Removal of mill scale and welding residues

- Cleaning tanks, silos, pipes, and steel constructions

- Restoration of historic facades and architectural details

- Increasing surface roughness to improve coating adhesion

- Strengthening structural elements through shot peening

- Cleaning industrial components and machinery

- Processing bridges, viaducts, and engineering structures

- Cleaning ship hulls, offshore platforms, and marine structures

TECHNICAL SPECIFICATION OF INGRITECH ABRASIVES |

|||||

| Types | Spherical | Angular | |||

| Steel shot S | Steel grit GP | Steel grit GL | Steel grit GH | Steel grit GS | |

| Spherical | Peened edges | Long life | Hard | Special | |

| Shape in use | Round | Angular “potatoed” | Angular “rounded edges” | Angular “sharp edges” | Per customer requirements |

| Hardness | 40-51 HRC | 47-56 HRC | 51-61 HRC | ≥60 HRC | As required |

| 390-530 HV | 460-630 HV | 510-700 HV | ≥697 HV | ||

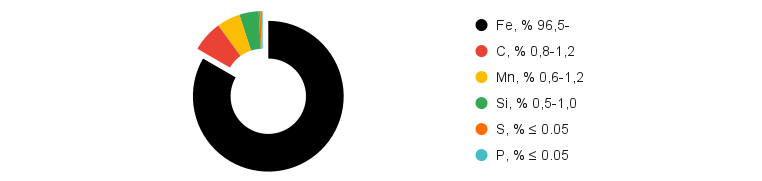

| Chemical composition – According to SAE J827 |

|

||||

| Standard deviation | ± 3Rc (± 80 HV) | ||||

| Microstructure | Tempered martensite with 15% retained austenite | Homogeneous, highly refined tempered martensitic structure obtained through precisely controlled processes ensuring fine and uniform iron and carbon distribution. Guarantees consistent microstructure, required hardness, and abrasion resistance. | |||

| Minimum density | > 7.0 g/cm³ | > 7.3 g/cm³ | |||

| Conductivity | Typically <30 μS/cm (low per ASTM D4940) | ||||

| Applicable standards | SAE J444, SAE J445, SAE J1993, ASTM D4940, SSPC-AB3 (on request) | ||||

Sieve analysis – SAE J444 + WAE |

|||||

Additional logistics information

- Packing: 25 kg polyethylene bags (carton + pallet 1000 kg) or big bags on pallets 1000 kg

- Country of origin: Ukraine

- Transport: across Poland and the EU – bulk or on pallets

- Delivery: free delivery for orders from 1 ton

- Lead time: most orders shipped within 2–3 business days

- Documentation: full technical documentation and quality certificates available on request

Trusted by clients across Europe

We successfully deliver to customers in Poland, Czechia, Germany, and Lithuania.

Our abrasives are used by both large industrial plants and specialized renovation and service companies.

Contact us – we offer:

- Individual quotations tailored to your needs

- Free technical consultations

- Option to order samples for testing

With best regards,

The INGRITECH Team