What is sandblasting and why was it popular?

Steel shot blasting is an effective and safe alternative to sandblasting with silica sand. For years, sand was a cheap and common abrasive, but due to serious health and environmental risks, it is now banned in many countries, including Poland. This article explains why steel shot is now the recommended solution.

Ban on sandblasting with sand – what do the regulations say?

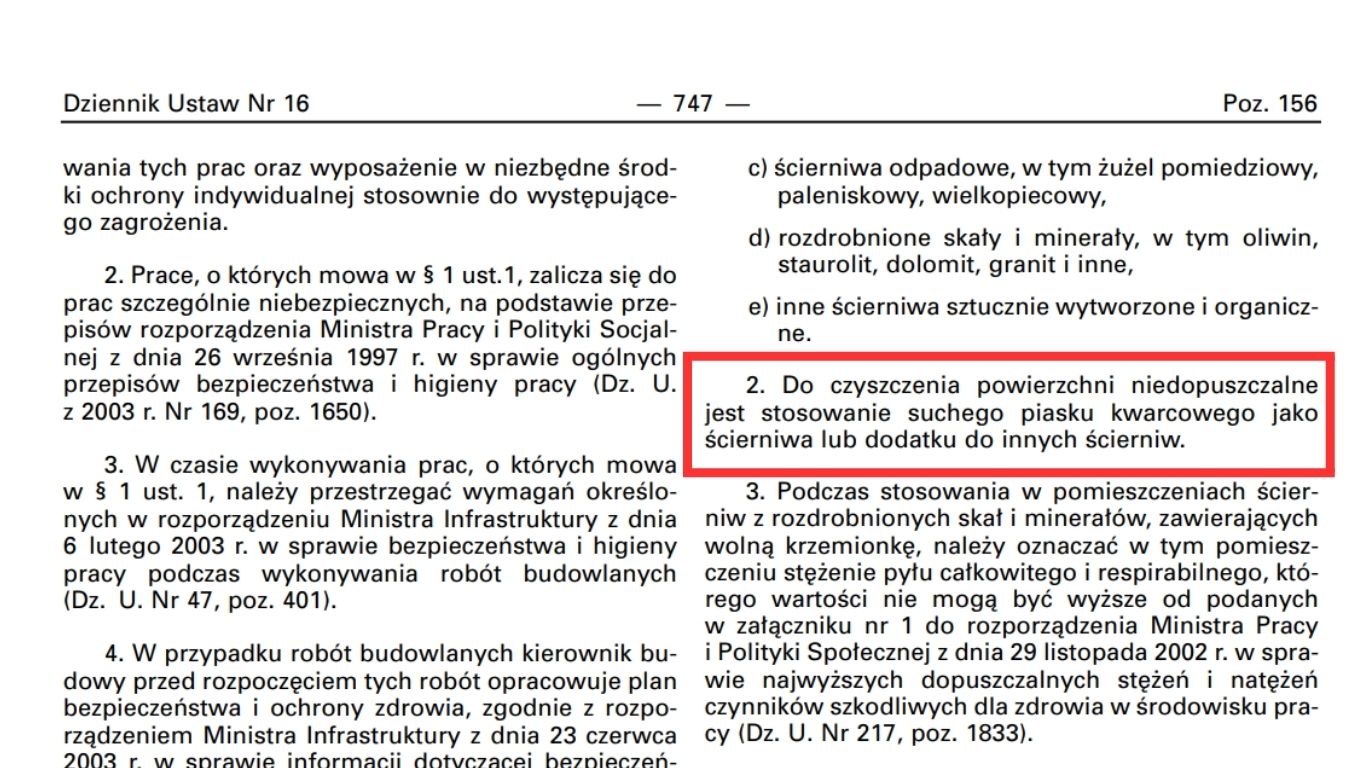

The ban on using quartz sand for abrasive blasting is not a trend or a result of technological evolution, but a hard legal requirement:

- Directive 2004/37/EC of the European Parliament and of the Council – classifies crystalline silica as a carcinogenic substance in the workplace.

- Polish Regulation of January 14, 2004 – bans the use of sand containing free silica in blasting equipment in Poland.

It’s also essential to follow health and safety regulations – exposure to silica dust may lead to severe occupational diseases.

Why is sandblasting with sand dangerous?

Health consequences

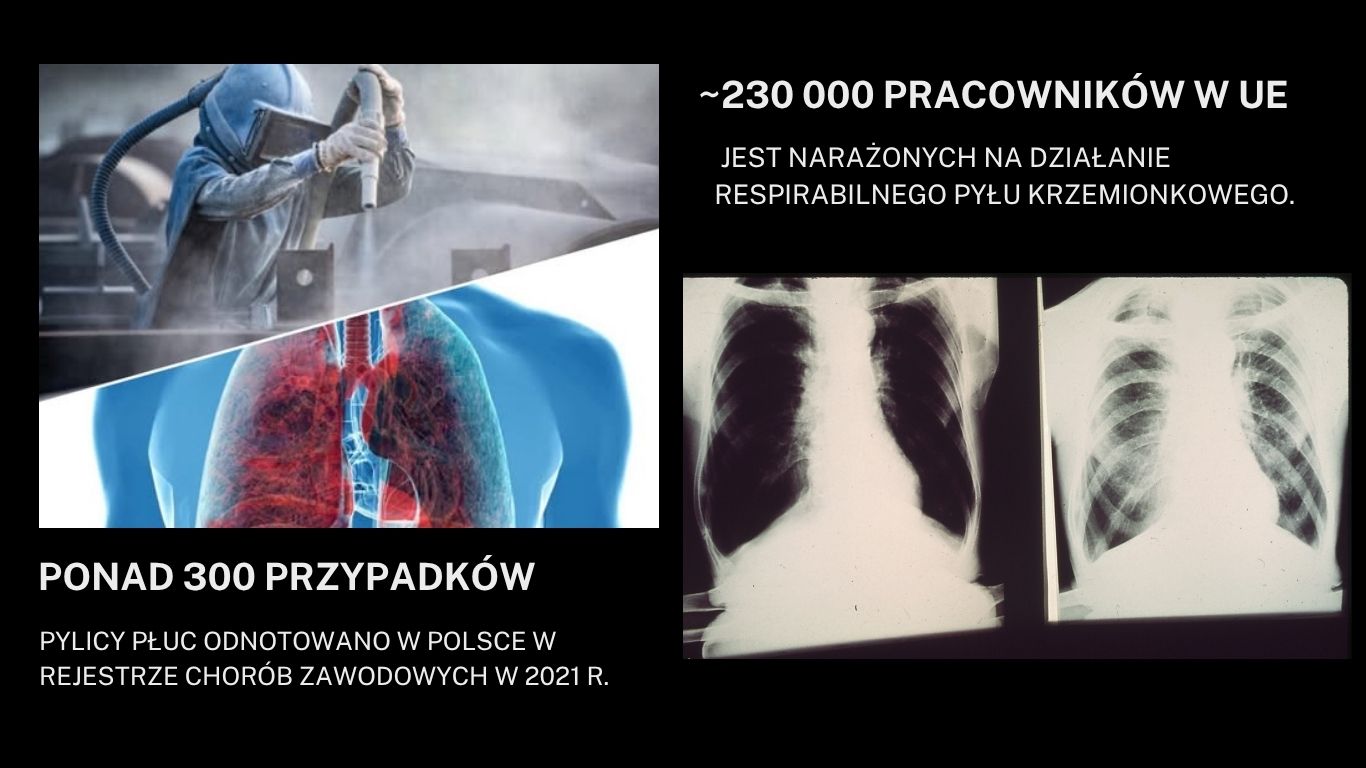

Inhaling fine quartz sand particles causes silicosis, a respiratory disease that may develop silently over years. Moreover, silica dust has a carcinogenic effect – confirmed by numerous independent studies. As seen in Germany and Italy, companies were legally forced to pay millions in compensation to workers diagnosed with silicosis or lung cancer due to long-term silica exposure.

Legal and financial consequences

- High fines for violating environmental and health & safety regulations.

- Risk of losing quality certifications, such as ISO 45001.

- Potential legal proceedings due to occupational diseases.

- Insurance issues and industrial audits.

Discover why steel shot is the safest and most effective material for metal surface treatment.

Shot blasting – a legal and modern alternative

Unlike quartz sand, steel shot and other blasting media are safe, efficient, and meet current EU standards. Their use reduces dust emissions, allows recycling, and cuts long-term operational costs.

| Parameter | Sandblasting with sand | Steel shot blasting |

|---|---|---|

| Dust emission | Very high | Low (with extraction systems) |

| Legal compliance | Prohibited | Allowed |

| Recycling | None | Reusable multiple times |

| Cleaning effectiveness | Moderate | High and precise |

| Long-term costs | Increasing (waste, health, penalties) | Stable and optimized |

Our offer includes various types of steel shot – both spherical and angular – tailored to processes like surface preparation, painting pre-treatment, or descaling.

Conclusion: Choose the Best Steel Shot Blasting Alternative to Sandblasting

Sandblasting with sand is an outdated, dangerous and illegal technology. Shot blasting is the industry’s future – compliant with regulations, efficient and safe for people and the environment.

Looking for a safe alternative to sandblasting with sand?

Check out our steel shot range – low-carbon and high-carbon, compliant with safety standards and ideal for replacing quartz sand in abrasive blasting. Contact our technical advisor – we’ll help you choose the right abrasive.