The Importance of Safety During Shot Blasting

Shot blasting is one of the most critical processes in preparing steel surfaces, commonly used in construction, automotive, and powder coating industries. However, despite its effectiveness, the process poses numerous health and environmental hazards. Therefore, safety during shot blasting becomes a key element not only from a legal perspective but also as an employer’s responsibility. Adhering to occupational safety regulations and investing in proper protective measures are essential requirements for conducting modern, sustainable production processes.

Main Hazards Related to Shot Blasting Safety

- Dust Emission – release of fine particles PM2.5 and PM10 that can cause respiratory diseases.

- Noise – often exceeding 100 dB, requires effective hearing protection.

- Risk of Mechanical Injuries – flying abrasive or processed components.

- Hazardous Substances – dust from paint, rust, or heavy metals can be toxic.

Learn more about hazards on the Central Institute for Labour Protection website.

Employer Responsibilities – Health and Safety Regulations

Every industrial facility where shot blasting is performed must comply with the Labor Code and safety regulations, such as the Ordinance of the Minister of Economy from October 30, 2002, regarding occupational safety during work involving exposure to dust.

- Occupational risk assessment

- Initial and periodic training

- Documented procedures and workplace instructions

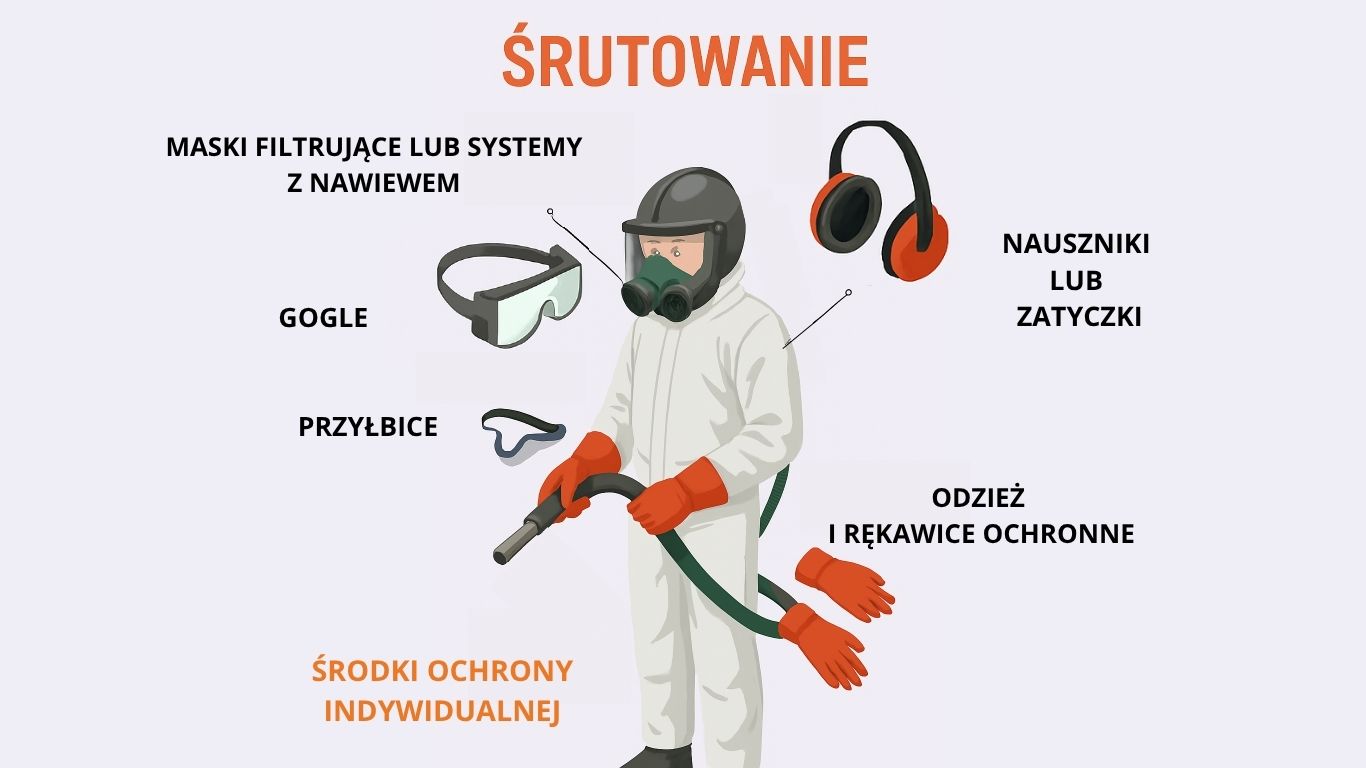

Personal Protective Equipment (PPE) for Shot Blasting

| Protection Element | Application |

|---|---|

| Filtering masks or air-supplied systems | Respiratory protection from dust |

| Face shields and goggles | Protection of face and eyes from debris |

| Earmuffs or earplugs | Noise reduction above 85 dB |

| Protective clothing and gloves | Skin protection from abrasives and sharp edges |

Collective Protection and Engineering Systems

Shot Blasting Booths with Filtration

Modern blasting booths are equipped with advanced dust filtration and ventilation systems, significantly reducing environmental emissions. Properly designed workspaces allow not only for effective dust extraction but also improved operator comfort, resulting in higher productivity and lower error rates.

Dust Extraction and Ventilation Systems

Essential components of any blasting hall include stationary cassette filters and extraction systems that effectively remove PM2.5 and PM10 particles from the air. These systems should be custom-designed based on abrasive type, chamber size, and operation intensity. Regular maintenance and filter replacement are key to ensuring long-term effectiveness.

Process Automation

Automated blasting machines and robotic processing lines significantly reduce operator exposure to hazardous factors. Automation improves not only safety but also process repeatability, cycle times, and abrasive consumption. Implementing such systems is a long-term investment in work quality, ergonomics, and overall plant efficiency.

Proper Workplace Preparation

Effective collective protection also includes properly prepared workstations. They should feature clear instructions, warning signs, first aid points, and easy access to personal protection equipment. Maintaining cleanliness – such as regular removal of accumulated dust and debris – also reduces accident risks and production delays.

Training and Employee Development

Regular position-specific and periodic safety training are crucial. They should cover not only basic safety rules but also updates on new equipment, technological changes, and legal requirements. Investing in employee skills builds awareness, shared responsibility, and strengthens the safety culture within the entire plant.

Environmental Protection in Shot Blasting

- Emission reduction – via filtration systems

- Waste management – separation of used abrasives and metal particles

- Emission monitoring – according to environmental norms and ISO 14001

Summary – Invest in Safety

The use of appropriate protective measures and engineering systems is an investment that results in fewer accidents, better work efficiency, and legal compliance.

Safety during shot blasting is not just a requirement – it is a standard that should be the foundation of every professional blasting facility.

Need Technical Advice or a Quote?

Check our offer of steel shot that meets current safety standards. Contact our technical advisor – we will help you choose the right abrasive.