What are Non-Metallic Abrasives?

Non-metallic abrasives are a group of specialized abrasive materials that – unlike metallic abrasives – do not contain any metallic components. As a result, they are lighter, completely resistant to corrosion, and gentler on the treated surface. Importantly, their structure and properties allow for effective removal of contaminants, coatings, or deposits while minimizing the risk of damaging the workpiece.

The most popular types of non-metallic abrasives include glass beads, which are ideal for precise matting and cleaning of delicate elements, aluminum oxide – a very hard material used for intensive grinding and coating removal, and silicon carbide, valued for its sharpness and ability to process very hard materials such as ceramics or glass.

Thanks to their properties, non-metallic abrasives are widely used in industries where surface integrity and high-quality finishing are crucial. They are especially common in aerospace – where precision is vital for safety, in the automotive industry – for renovation and surface preparation before painting, in glass manufacturing, as well as in heritage conservation, where gentle processing and preservation of the original structure are required.

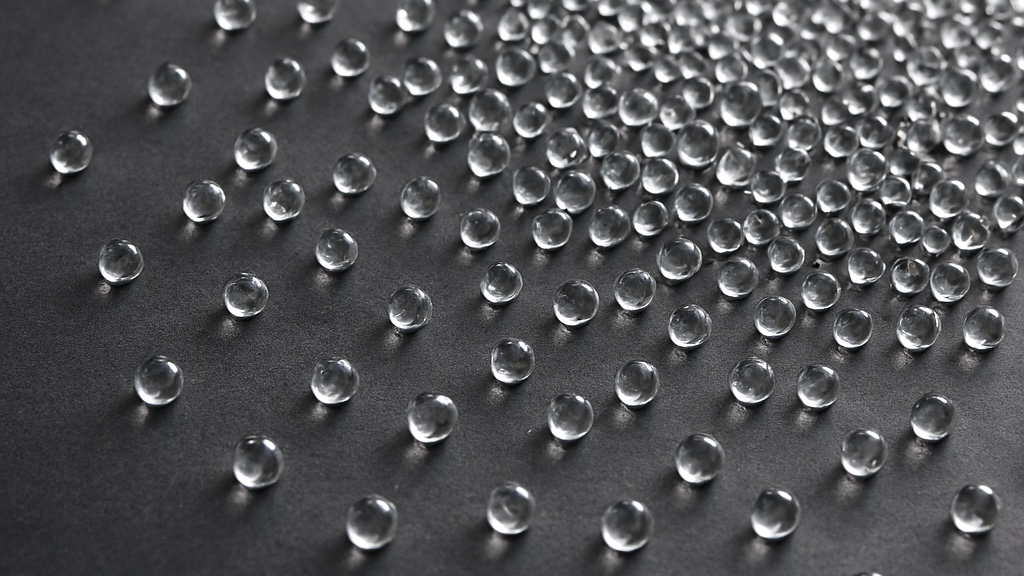

Glass Beads – Precision and Cleanliness

Glass beads are dust-free, chemically inert abrasive media. Due to their spherical shape, they provide uniform matting of the surface without damaging it. They can be reused multiple times, which reduces costs and minimizes waste generation.

- Perfect for cleaning molds, matting aluminum, and stainless steel

- Safe for operators – free from crystalline silica

- Reusable for up to several cycles

Learn more about glass beads in our offer.

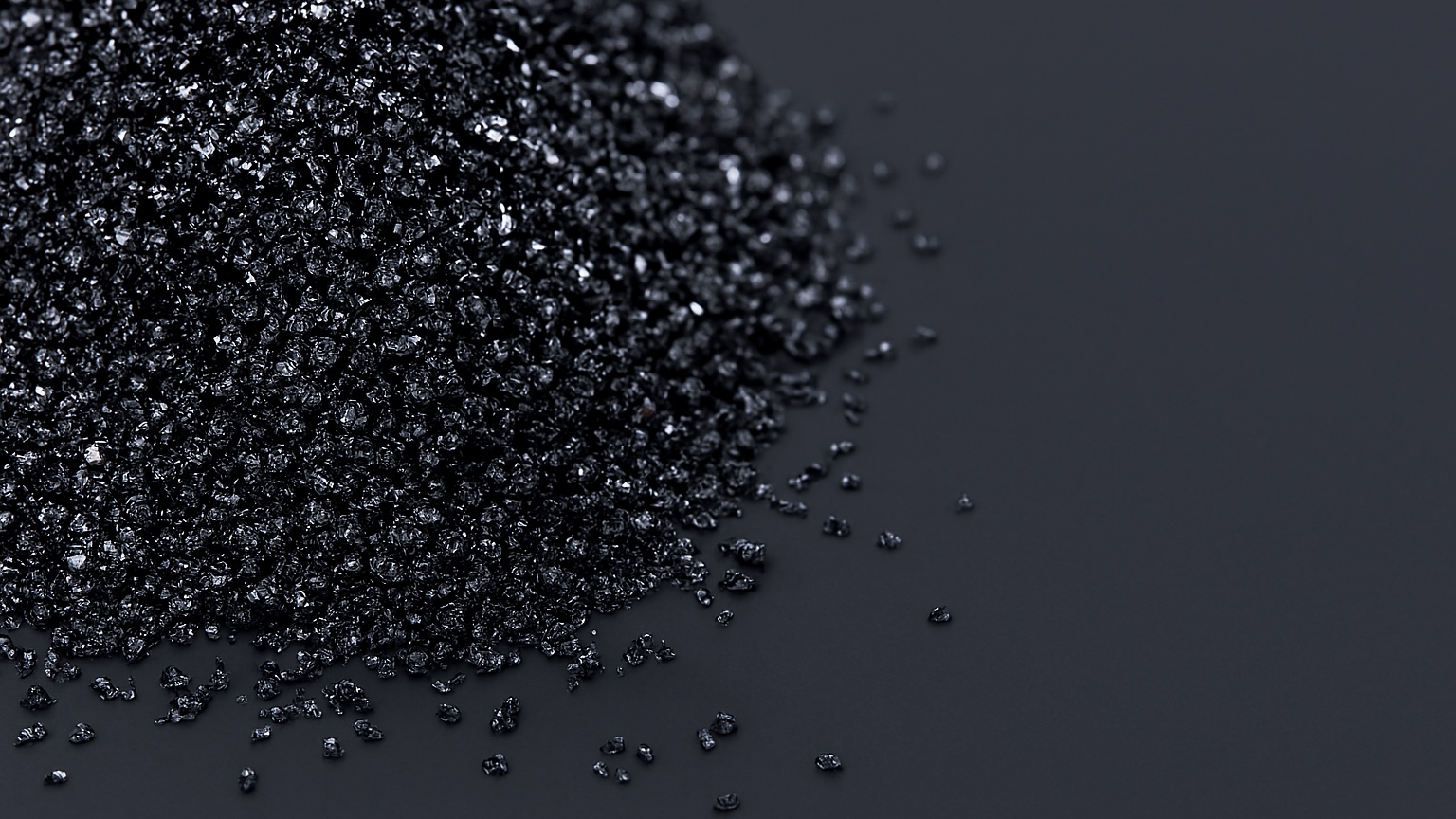

Aluminum Oxide – Maximum Hardness and Performance

Aluminum oxide (Al₂O₃) is one of the hardest known non-metallic abrasives. It offers excellent wear resistance and high efficiency. It is ideal for grinding, cutting, and treating surfaces that require intensive mechanical action.

Applications:

- Grinding stainless steel and metal alloys

- Surface preparation for powder coating

- Removal of coatings and hard-to-clean contaminants

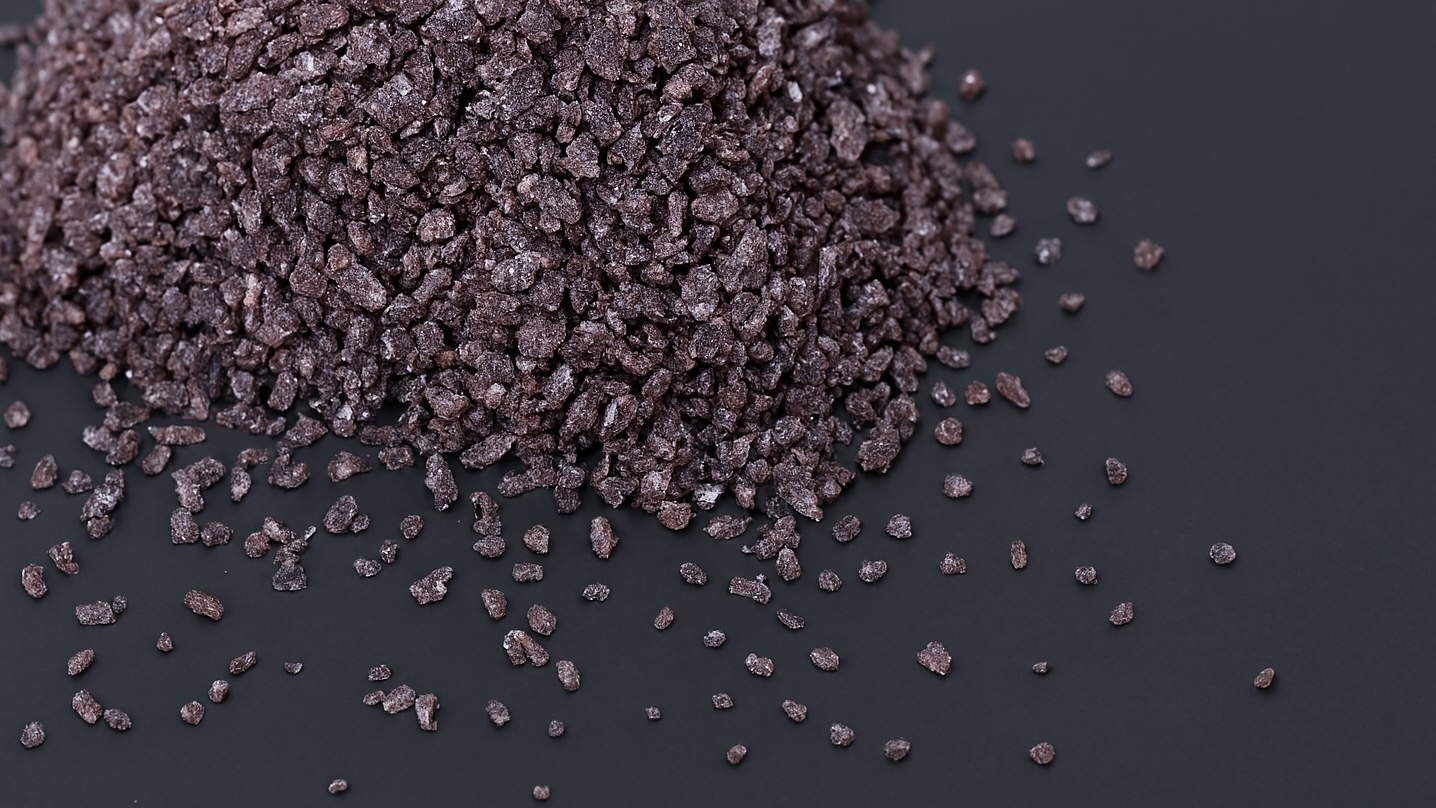

Silicon Carbide – Sharpness and Precision

Silicon carbide (carborundum, SiC) is an ultra-hard synthetic abrasive with exceptional physical and chemical properties. It features sharp grain edges, chemical resistance, and good thermal conductivity. Thanks to these qualities, it removes material quickly and precisely while maintaining stable processing parameters.

It is used in the processing of glass, ceramics, natural stone, and composite materials. It also performs well in processes carried out at high temperatures and in aggressive chemical environments. Its sharpness, durability, and versatility make SiC indispensable in tasks requiring maximum precision and high performance. It ensures long tool life and greater overall efficiency of the process.

Comparison of Non-Metallic Abrasives

| Abrasive Type | Hardness (Mohs) | Reusability | Typical Applications |

|---|---|---|---|

| Glass beads | 5-6 | Yes, up to several cycles | Matting, cleaning delicate surfaces |

| Aluminum oxide | 9 | Yes | Grinding, coating removal, cutting |

| Silicon carbide | 9.5 | Yes | Processing ceramics, glass, stone |

Why Choose Ingritech?

Ingritech has been supplying modern and safe non-metallic abrasives for industrial use for years. Our product range includes glass beads, aluminum oxide, and silicon carbide – materials that guarantee high efficiency, precision, and minimal environmental impact. With our products, the abrasive blasting process becomes not only faster and cleaner but also significantly more cost-effective.

Our competitive advantage lies not only in our wide product range but also in our comprehensive customer support at every stage of cooperation.

- We provide professional technical consulting and help in selecting the optimal abrasive, tailored to the specific technological process and desired final effect.

- We ensure constant product availability in stock, enabling our customers to maintain production continuity without downtime and guaranteeing on-time delivery.

- We maintain high consistency of material parameters, so every batch of supplied abrasive meets the same strict quality standards, ensuring predictable, repeatable, and satisfactory processing results.

Ecology and Safety

All our non-metallic abrasives are free from crystalline silica, reducing the risk of respiratory diseases among operators (source: OSHA). In addition, their reusability minimizes waste, supporting sustainable production.

Find the Perfect Abrasive

If you are unsure which type of abrasive will work best for your process, our experts will help you select the right solution.