Description

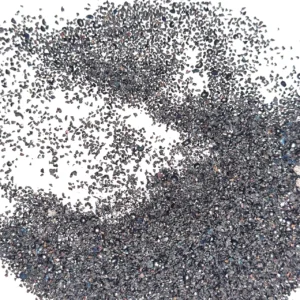

Brown Fused Alumina (BFA)

Brown fused alumina is a durable and wear-resistant abrasive material produced by fusing bauxite in electric arc furnaces. With a high hardness rating (9 on the Mohs scale) and excellent wear resistance, it is ideal for processing metals, glass, ceramics, and other hard materials.

Key Advantages:

◯ High hardness and wear resistance – ensures effective grinding and surface cleaning.

◯ Stable chemical composition – safe to use, free of harmful contaminants.

◯ Low dust generation – maintains a clean working environment.

◯ Versatile applications – suitable for various mechanical processes.

◯ High temperature resistance – melting point approx. 2200°C.

Physical and Chemical Properties of Brown Fused Alumina (BFA):

◯ Shape: Solid, angular particles

◯ Color: Brown

◯ Odor: Odorless

◯ Water Solubility: Insoluble

◯ Hardness: 9.0 (Mohs scale)

◯ Microhardness: 1800–2400 kgf/mm²

◯ Bulk Density: ~4 g/cm³

◯ Specific Gravity: ~4.6 g/cm³

◯ Melting Point: ~3722°F | 2050°C

◯ Elastic Modulus: 7.6 × 10¹¹ N/m²

Chemical Composition:

Al₂O₃ – 88.0–99.0%

Fe₂O₃ – 2.0–3.0%

TiO₂ – 3.0–5.0%

SiO₂ – 2.0–3.0%

CaO – 0.6–0.8%

MgO – 0.3–0.5%

C – 0.3–0.4%

FEPA (F) Grain Sizes:

| FEPA (F) | Mesh № | Size (mm) |

|---|---|---|

| F24 | 20–40 | 0.60–0.85 |

| F36 | 30–50 | 0.425–0.60 |

| F46 | 36–54 | 0.30–0.425 |

| F60 | 45–60 | 0.212–0.30 |

| F80 | 54–70 | 0.18–0.212 |

| F100 | 70–100 | 0.15–0.18 |

| F120 | 80–120 | 0.125–0.15 |

| F150 | 100–140 | 0.106–0.125 |

| F180 | 120–140 | 0.09–0.106 |

| F220 | 140–170 | 0.063–0.09 |